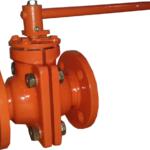

DESIGN, STANDARD & FEATUES

TECHNICAL SPECIFICATIONS

CONSTRUCTION MATERIAL

LOW TORQUE FOR EASIER OPERATION

DESIGN, STANDARD & FEATUES

- Areas where highly corrosive materials are used in the chemical process and plants.

- Industries where the critical application like food, pharma and fine chemicals.

- To control environment pollution.

- Best quality in class with excellent performance.

- Excellent corrosion resistance to the chemicals.

- Maintenance Free / Long Services life cycle / Easy Installable, ensuring cost reduction in production and maintenance.

- High Voltage electric spark test – all lined components.

- Standard Hydraulic Test(15 kg/cm²) of body and seat(10 kg/cm²)

- Virgin lining materials used – FEP/PFA.

- Size : 50 NB to 500 NB

- Thickness : 3.0 to 3.5 mm Mini. Over all wetted parts.

- Spark Test : 15k.v.D.C

- Type : FEP/PFA

- Services : (FEP) Max – 160°C

- Temp. : (PFA) Max – 205°C

TECHNICAL SPECIFICATIONS

Description | MOC |

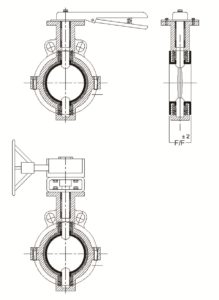

Design std | BS 5155 |

Body | ASTM A216 GR WCB / CF8 / CF8M |

Flapper | ASTM A216 GR WCB / CF8 / CF8M (Fabricated: MS / SS304 / SS316) |

Lining | PTFE / PFA / FEP / PVDF / HDPE / PP |

Lining thickness | 3mm Minimum |

Flange connection | ANSI B16.5,#150 / Customer requirement |

Spark test | 15 KVDC |

CONSTRUCTION MATERIAL

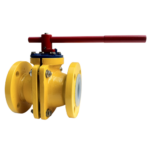

- Valve bodies available in Ductile iron material – ASTM A395 (60-40-18) & in CAST carbon steel ASTM A216WCB

- Valve bodies can be supplied in all grades of stainless steel material as per request

LOW TORQUE FOR EASIER OPERATION

- Requires significantly lower torque for operation than equivalent butterfly valves

- Easy manual operation and considerably low actual figures